Product Description

ANEST IWATA was the first in the world to develop the air-cooled, oil-free, scroll-type vacuum pumps. These oil-free, scroll vacuum pumps are compact and emit less noise and vibration than other dry vacuum pumps. They are highly valued by customers who need clean, high quality vacuum, especially in the analytical and semiconductor related fields.

The DVSL scroll pumps are equipped with a dry vacuum system so there is no need for lubricating oil or sealing water. The absence of gears means that it is low-maintenance and there is no need to change gear oil and no risk of lubricating oil leaks. Generator powered vacuum keeps the installation area clean. It is equipped with a water cooling system which eliminates the need to control water cooling on site. DVSL pumps are excellent in displacing water vapor. Low power variance between atmospheric pressure and maximum pressure allows repeated, continuous operation between atmospheric pressure and vacuum. These pumps use up less energy and can lead to savings in the vacuum area. 24-Hour operation secured.

Features

- DVSL scroll pumps are equipped with dry vacuum system without using lubricating oil or sealing water.

- No gears result in no need to exchange of gear oil and no risk of leaked lubricating oil.

- Easy – maintenance available.

- Generated clean vacuum keeps installation area clean.

- Equipped cooling system frees from the trouble of controlling cooling water and selecting installation site.

- Excellence in displacing water vapor.

- Reliable Design – Little power variance between atmospheric pressure and the ultimate pressure allows repeated continuous operation between atmospheric pressure and vacuum.

- Standard equipped hour meter enables easy daily operation. Only supplied with DVSL-500C / 501C.

- Excellence in energy-savings in vacuum area. 24 hrs operations secured.

Precautions for Dry Scroll Vacuum Pumps

- Evacuation Gases

This pumping system is suitable for clean processes only. Do not use explosive, flammable, toxic or corrosive substances or substances, which contain chemicals, solvents or particles. FluidX will not perform maintenance work on pumps which have used hazardous substances.

- Ambient Temperature

Use at ambient operation temperature in the range of 5° C to 40° C.

Specifications

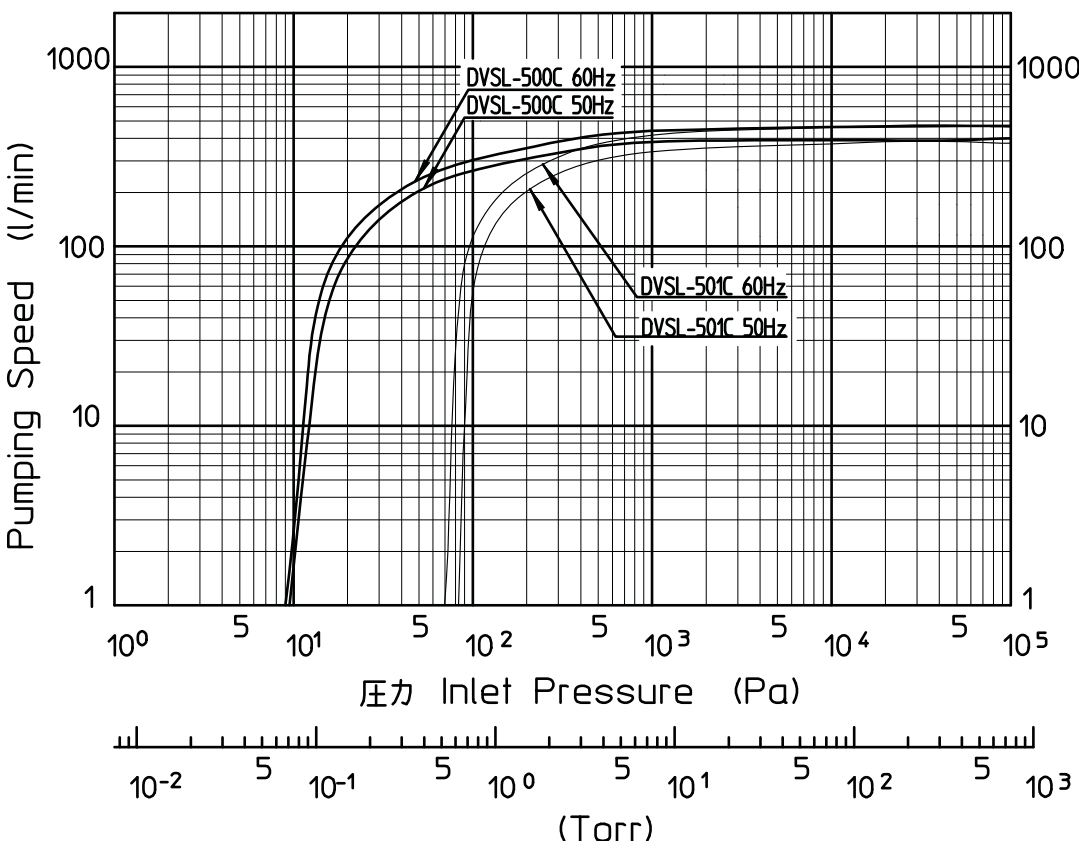

- Pumping Speed at 50 Hz: 430 L/min | 15.2 CFM

- Pumping Speed at 60 Hz: 520 L/min | 18.4 CFM

- Ultimate Pressure: ≤ 30 Pa | ≤ 2.3 x 10-1 Torr

- Max Inlet Pressure: Atmospheric pressure

- Motor Power: 900/1100 W

- Motor Type: 3-Phase

- Voltage: 200 V, 208 V, 230 V, 380 V, 415 V, 400 V, 460 V

- Noise Level: ≤ 64 dB(A)

- Noise Level at Air-Flush: ≤ 69 dB(A)

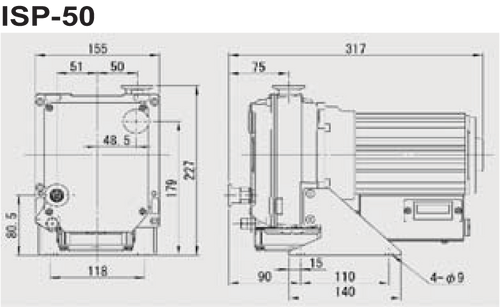

- Dimensions: 317mm W x 491mm L x 280mm H

- Weight: 36 kg

- Water Vapor Capacity: 250 g/day

- Air Flush: 10 L/min

- Intel Connection: NW25 (with RC 1/2)

- Outlet Connection: NW25

- Cooling System: Air-Cooled

- Ambient Operating Temperature: 5° C - 40° C | 41° F - 104° F

- Back-up-Material: Silicon rubber

- Displacement at 50 Hz: 430 L/min

- Displacement at 60 Hz: 520 L/min

Pumping Speed

Applications

- Vacuum Forming

- Deaerator

- Vacuum Chuck

- Regenerative

- Vacuum Cooling

- Vacuum Drying only for water based

- Ceramic Industry

- Gas Substitution

- Pumping for Electron Tube